Yesterday we visited a gage block factory. Making gage bocks is an interesting process. This factory can make about 1000 blocks a day.

Gage blocks come in several grades. The most common is a grade for use in the shop called AS-2. These are typically within 25 millionths of an inch of the size marked.

Better gage blocks are grade AS-1. These are within +8 and –4 millionths of an inch. And grade 0 gage blocks are within +4 and –2 millionths of an inch of the marked size.

Here’s how they are made. They start with the raw material that is sawed to size. The steel is a special grade called “Gage Block material”.

The first step is surface grinding. This gets them to the rough size. It probably finishes the non-working surfaces.

Next is rough lapping. These machines work on a lot of gage blocks at a time. The rough lapping machines are in the machine shop.

Here is what that machine looks when it is open. The gage blocks go on the silver doughnut.

These intermediate lapping machines are in more of a lab environment. They are getting the gage blocks closer to size.

At this point the gage blocks are laser marked with their size. They also get a serial number. The bright dot near the right center is the laser at work.

Now the gage blocks move to final lapping. Each workbench has a lapping machine and a comparator. The gage blocks go back and forth between the lapping machine and the comparator several times.

Here is a lapping machine opened up. The gage blocks go in the rectangular holes in the yellowish disk.

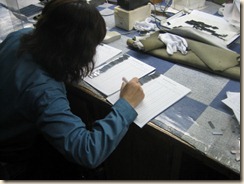

The operators spend most of their time measuring.

Once finished, the gage blocks are given a final measurement.

This is where the various grades are separated. The measurements are recorded and the gage blocks separated by grade. The gage blocks that ‘make the grade’ are put in the grade 0 or grade AS-1 piles. Those that don’t go in the AS-2 pile.

The gage blocks are oil coated and wrapped. Ever notice how neat the wrapping is? She is doing a block about every two seconds.

Finally, the gage blocks are put in sets.

The plant is adding an inventory of pin gages. Just setting up the inventory is a daunting task. These women are sorting a shipment of pin gages. The will go on the blue shelves on the right.

Pin gages come in sizes from 0.011 to 0.500, by 0.001 inches. That’s 490 sizes. But you can get “minus” pin gages and “plus” pin gages, so that doubles the number to 980 sizes. Metric? That’s more sizes.

No comments:

Post a Comment