Scott's test post

Monday, January 8, 2024

Thursday, November 29, 2012

Where We Went in China

Monday, November 12, 2012

Carbide, Carbide, Carbide

On Saturday we visited five or six carbide factories. One reason we were able to visit so many is that they are all within a mile of each other. This is not unusual in China. The first factory we visited is the oldest. Over the years people left that factory and started their own. Now there are about 60 in this “village”.

These are “round” carbide factories. They are grinding tools out of solid carbide. So, for example, to make an end mill, they start with a round blank slightly larger in diameter and slightly longer than the finished end mill. They grind the blank to finished diameter and length, and then grind the flutes.

While grinding the blanks may be done on fairly simple machines, grinding of the cutting edges is mostly done on CNC grinders.

(Click the photos for a larger view.)

This tray is next to a CNC grinder. You can see blanks at the bottom and cutting tools at the top. I’m not sure what the tools are or if they’re finished at this point.

It’s impossible to tell what is going on inside a CNC grinder. All you can see is a big spray of coolant. The spindle is horizontal at the top of the coolant “waterfall”. You can see where a second grinding wheel can be mounted on the right end of the spindle.

The original factory has some sophisticated CNC grinders, but it also has a lot of older equipment too.

This is one of the better lit shops in the Changzhou Huake Tool Company. That’s because it has the largest windows.

The Changzhou Huake Tool Company makes more than carbide cutting tools. This is a face mill. The lady who is looking at it is the purchasing agent for a company that actually uses tools this large. They make the machinery for making copper tubing. She spent the day escorting us to all these factories.

This is a typical exterior view of the Changzhou Huake Tool Company. It was raining off and on and that is mostly water you see in the puddles. Let’s just say that things can get slippery on a wet day.

Let’s get back to grinding carbide.

One of the plants we visited is as nice as any in the world. Wansui Tools uses all German machines, installed with proper ventilation add coolant filtering. Not a spec of dirt in this plant. There are another six grinders to the right of the columns at the right of this picture.

Not all the plants are as nice as Wansui. This place has 10 machines crammed into a pretty darn small room. We did not recognize the brand of these CNC grinders.

The metrology department includes all the proper instruments including this laser measuring device. We never figured out how many zeros to the right of the decimal this thing works to. Let’s just say it’s a lot.

One of the nicer factories we visited made turning and milling tool holders for carbide inserts. Here’s an indexable turning tool that will probably not appear in the LittleMachineShop.com catalog.

Sunday, November 11, 2012

SIEG Visit

The latest from Chris in China:

I had a good meeting with SIEG while I was in Shanghai. You can expect to see some interesting products over the next months.

They were working on some LittleMachineShop.com machines while I was there.

(Click the photos for a larger view.)

Here are some model 4200 lathes in final assembly. He’s test driving them to ensure everything operates properly.

And yes, they really do check each LittleMachineShop.com machine to ensure it meets specifications.

Here is a fleet of mini mill heads ready for the next step.

Here are a couple of pallets off mini lathe beds ready for final grinding. I noticed them unloading a truckload of these as I was arriving.

SIEG does the critical machining in their own shop. He’s setting up to grind the bed ways for a mini lathe.

They are assembling electrical sub-assemblies such as control boxes.

Tuesday, October 30, 2012

Going to China Once Again

I'm headed to China next week, and I hope to resume blogging while I am there. I am writing this entry to help me remember how to do this.

I have to figure this out again, and then update Carl, as I know that I will not be able to post to this blog when I am in China. I have to email entries to Carl and he posts them on the blog.

I leave LAX on 5-Nov and I'll arrive in China midday on 7-Nov. You might see a blog as early as 9-Nov in the US.

Wednesday, April 20, 2011

A Darn Big Trade Show

I can’t find anything that says the Canton Fair is the largest trade show in the world, but I suspect it is, at least by some measure. It’s far larger than any other I’ve attended, and I’ve been to at least a few large ones (remember Comdex?).

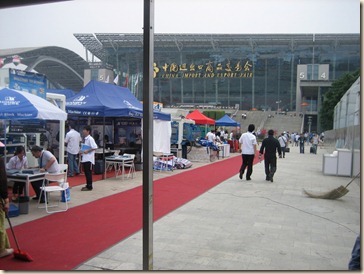

The Canton Fair, officially called the China Import and Export Fair is held at the China Foreign Trade Centre. This complex is over 1/2 mile long and comprises 16 halls, most of which contain multiple floors (up to 4).

A snapshot can’t start to show the scale of this place because it can only show a small percentage of the buildings.

This walkway is between two sections of the facility. It’s at least a quarter mile long, but is only abut half as long as the main walkway down the center of the building.

Because of a lack of space, the fair must be held in three phases, with the product categories split between phases. Each phase is 5 days long with a three day break between to change exhibits to the different product categories. Following are the product categories. Note that they are not too restrictive.

Phase 1

- Electronics & Household Electrical Appliances

- Lighting Equipment

- Vehicles & Spare Parts

- Machinery

- Hardware & Tools

- Building Materials

- Chemical Products

Phase 2

- Consumer Goods

- Gifts

- Home Decorations

Phase 3

- Textiles & Garments

- Shoes

- Office Supplies, Cases & Bags, and Recreation Products

- Medicines, Medical Devices and Health Products

- Food

What’s to see?

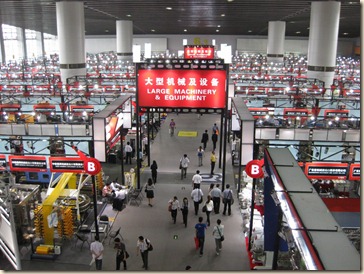

Here is a view of one of the halls from one level up.

Note the product category is ‘large machinery’. Not ‘metalworking machinery’, or such like. That’s a pretty broad category and that is born out by the types of machinery on exhibition.

Need to make rope? That’s an interesting machine.

Fill a bottle? There were all manner of package making and filling machines.

Make Oreos? This machine adds the crème filling between the two cookies.

Make concrete. Some vendors used models, but the real thing is outside.

Yes, there were metalworking machines too,

Plus food mixers and press brakes.

And diaper-making machines.

In summary, everything you can imagine. And this is in just one hall.

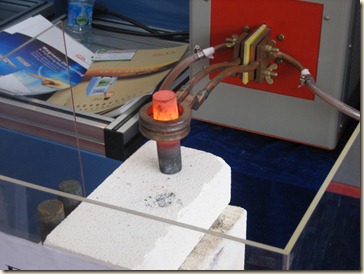

There were the usual Chinese safety guards. The plastic shield around the sides of this red hot induction heated steel rod provides plenty of protection.

And it’s only needed because the whole display is in the isle of the trade show. Look mom, what a pretty red…

And the usual great slogans.

SIEG had a booth there.

One of the amazing things about large gatherings of people in China is the lack of waiting in lines. We registered for the show in about 10 minutes, including meeting with three different departments because they couldn’t figure out what to do with us.

I’m guessing there were 150,000 attendees there, yet we waited abut two minutes for lunch in the largest food court I have ever seen. It’s about the size of a football field. This photo is taken from the center of the room. There are at least two McDonalds in this exhibition complex.

We worked pretty hard to get through the sections we need to see, which were large machinery, small machinery, and tools. We only had a little time for the fun stuff like consumer electronics, motorcycles, construction equipment, and computers.

Weight lifting equipment

In-line skateboards.

You can’t just put the babies in the bicycle basket…

A pink scooter anyone? ((We saw one of these on the street in Shanghai)

Just writing this makes my feet sore. We figured we put in over 10 miles a day. That’s enough.

Monday, April 18, 2011

How Do You Make a Gage Block?

Yesterday we visited a gage block factory. Making gage bocks is an interesting process. This factory can make about 1000 blocks a day.

Gage blocks come in several grades. The most common is a grade for use in the shop called AS-2. These are typically within 25 millionths of an inch of the size marked.

Better gage blocks are grade AS-1. These are within +8 and –4 millionths of an inch. And grade 0 gage blocks are within +4 and –2 millionths of an inch of the marked size.

Here’s how they are made. They start with the raw material that is sawed to size. The steel is a special grade called “Gage Block material”.

The first step is surface grinding. This gets them to the rough size. It probably finishes the non-working surfaces.

Next is rough lapping. These machines work on a lot of gage blocks at a time. The rough lapping machines are in the machine shop.

Here is what that machine looks when it is open. The gage blocks go on the silver doughnut.

These intermediate lapping machines are in more of a lab environment. They are getting the gage blocks closer to size.

At this point the gage blocks are laser marked with their size. They also get a serial number. The bright dot near the right center is the laser at work.

Now the gage blocks move to final lapping. Each workbench has a lapping machine and a comparator. The gage blocks go back and forth between the lapping machine and the comparator several times.

Here is a lapping machine opened up. The gage blocks go in the rectangular holes in the yellowish disk.

The operators spend most of their time measuring.

Once finished, the gage blocks are given a final measurement.

This is where the various grades are separated. The measurements are recorded and the gage blocks separated by grade. The gage blocks that ‘make the grade’ are put in the grade 0 or grade AS-1 piles. Those that don’t go in the AS-2 pile.

The gage blocks are oil coated and wrapped. Ever notice how neat the wrapping is? She is doing a block about every two seconds.

Finally, the gage blocks are put in sets.

The plant is adding an inventory of pin gages. Just setting up the inventory is a daunting task. These women are sorting a shipment of pin gages. The will go on the blue shelves on the right.

Pin gages come in sizes from 0.011 to 0.500, by 0.001 inches. That’s 490 sizes. But you can get “minus” pin gages and “plus” pin gages, so that doubles the number to 980 sizes. Metric? That’s more sizes.